No Data Found

Your Diamond's Creation

Your laboratory-grown diamond is chemically identical to every other diamond on earth. However, instead of mined diamonds, which formed beneath the ground billions of years ago, your diamond was grown in controlled laboratory conditions using sophisticated methods of chemical synthesis. There are two specific approaches to diamond creation:

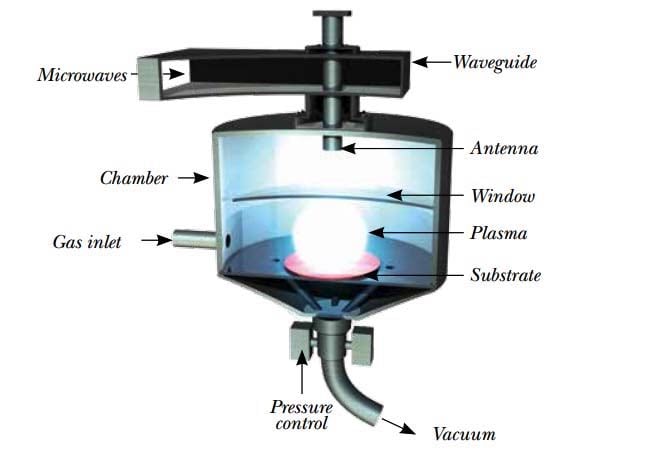

Chemical Vapor Deposition (CVD)

The Chemical Vapor Deposition (CVD) process releases carbon from plasma. This involves superheating hydrocarbon gas in a vacuum to between 3,000-4,000C, at which point the carbon atoms begin to separate from their molecular bonds. Those atoms descend and land on a flat wafer of previously grown synthetic diamond and grow in vertical layers. This substrate is square for jewelry applications but the shape can vary for other applications in medicine, communications and technology.

High Pressure High Temperature (HPHT)

The High Pressure High Temperature (HPHT) process replicates the natural conditions under which diamonds formed 100 miles below the surface due to subduction. A carbon source, a diamond seed and a metallic catalyst go into an octahedral cell. The cell is placed into a massive mechanical press where the contents are heated near 1,500 C and subjected to staggering pressure. The melting metal dissolves the carbon and the pressure causes precipitation to the diamond seed, growing a larger diamond. The level of pressure from these immense presses has been compared to what you’d experience if you balanced a jumbo jet on the tip of your finger.

Rough to polish

Diamond cutting is the art, skill and science of transforming a raw crystal into a polished, faceted diamond. As the hardest material known to man, cutting and shaping a diamond requires specialized knowledge, tools and skill.

1) Planning: This rough octahedron crystal is studied and its growth directions and inclusions are mapped.

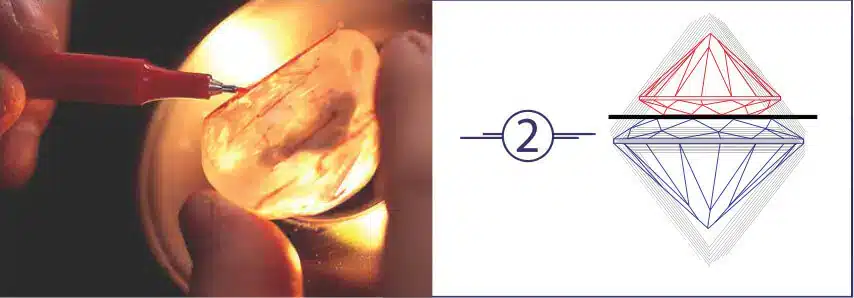

2) Marking: Once the plan is determined, the crystal is marked for primary sawing.

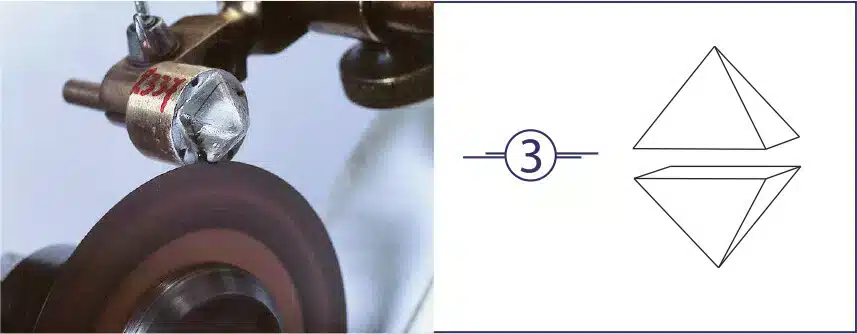

3) Sawing: A carbon-fiber blade coated with diamond-grit makes the first cut. It will take several hours to saw this crystal into two pieces; each of which will become a polished diamond.

4) Bruting: The two pieces spin in opposite directions, grinding against each other to smooth the edges and create a round outline.

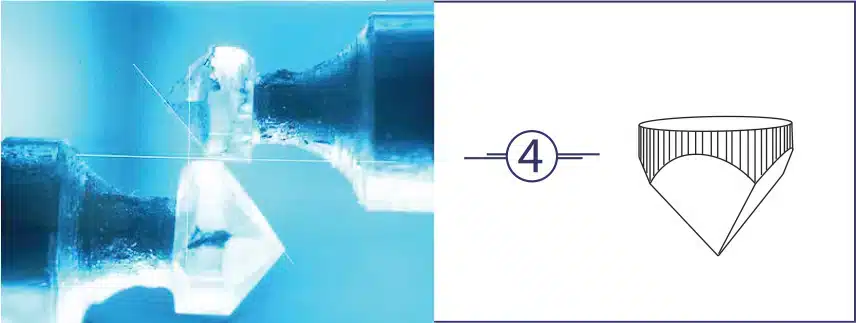

5) Polishing: A spinning wheel coated with diamond-grit is used for blocking, crossworking and brillianteering, the process of placing, shaping and smoothing all facets to final polish.

6) Inspection: Once finished, the diamond is thoroughly boiled in acid and examined to ensure that it meets the producer’s expectations and quality standards.

Diamond Grading

Following the diamond cutting process and prior to being sold loose or mounted into jewelry, diamonds are typically submitted to gemological institutions such as IGI for quality assessment. Four main factors are considered when judging a diamond’s quality and value. They are the diamond’s 4C’s: Carat weight, Color, Clarity and Cut.

IGI screens every diamond using state of the art technologies to determine naturally mined, laboratory grown or simulant origin. Experienced graduate gemologists conduct further assessment in controlled conditions, detailing relevant gemological characteristics according to the strictest international system.

Uniquely yours

Your diamond is exceptional and distinctive. No two diamonds are alike. Yet all diamonds have certain features in common that allow experts to compare and evaluate them.

The name diamond is derived from the ancient Greek “adamas” meaning unbreakable, untamed and unconquerable. Diamonds have been treasured as gemstones ever since they were discovered. In our modern age the word “diamond” continues to evoke images of elegance, style and glamour.

Diamond sparkles and dazzles. Diamond symbolizes purity and strength. And the story of your diamond is uniquely yours.

Important Limitations

This report provides an opinion by IGI, and neither IGI’s original client nor any purchaser of the article shall rely on this report as a guarantee, appraisal, or warranty. Opinions provided by third-party laboratories may vary depending on when, how and by whom the article was examined. Technologies employed in treatmentxs, processing and synthesis are continuously evolving, and hence it may not always be possible to determine the origin of the article using the then-latest available techniques. Neither IGI nor any of its employees shall, at any time, be liable for any difference of opinion or discrepancy which may result from the application of other assessment and/or identification methods, tools or techniques. IGI has provided this report for a small fee compared to the actual and potential value of the subject article and has no financial interest in the sale/purchase of the item described in this report. Important notice: This report is subject to IGI’s Terms and Conditions, which can be found at www.igi.org/reports/terms-and-conditions. The limitations included in our Terms & Conditions apply to every person reading or receiving this report.